Comprehensive Membrane Switch Manufacturer for Specialized Applications

Comprehensive Membrane Switch Manufacturer for Specialized Applications

Blog Article

Checking Out the Manufacturing Process of Membrane Switch for Different Industries

The manufacturing process of Membrane switches is an intricate venture that demands accuracy and interest to information. From picking ideal products to executing extensive quality control measures, each action plays a vital function in guaranteeing capability. Different sectors, consisting of automobile and clinical, count on these parts for their unique applications. Recognizing the complexities of this procedure reveals significant insights right into how these buttons are created and their impact across diverse industries.

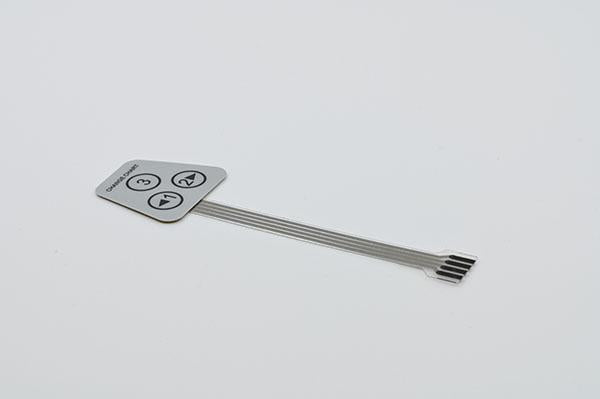

Recognizing Membrane Switches Over: An Introduction

Key Materials Used in Membrane Switch Manufacturing

In Membrane switch production, the selection of essential materials considerably affects capability and longevity. Conductive products, adhesives, and coatings play essential roles, while substrate choice affects total efficiency and reliability. Understanding these parts is vital for optimizing the design and production of Membrane switches.

Conductive Materials Introduction

Conductive products play an essential duty in the performance of Membrane buttons, making certain dependable electrical connections within the gadget. Frequently utilized products consist of silver, copper, and carbon-based inks, each offering distinct benefits. Silver is preferred for its high conductivity and resilience, making it suitable for applications requiring durable performance. Copper, while slightly less conductive than silver, is an economical option typically utilized in printed circuits. Carbon-based inks supply a flexible alternative, ideal for applications where flexibility and lower prices are prioritized, although they have actually reduced conductivity compared to metal options. The choice of conductive products straight impacts the total reliability, life expectancy, and performance of the Membrane button, making it a crucial consideration in the manufacturing process.

Adhesives and Coatings

Adhesives and layers are necessary components in the manufacturing of Membrane buttons, providing vital bonding and protective residential or commercial properties. These products ensure that various layers of the switch, consisting of visuals overlays and wiring, adhere securely to each other, boosting durability and capability. Commonly utilized adhesives include pressure-sensitive adhesives (PSAs) and epoxy-based solutions, which provide solid bond and resilience. Coatings, such as polyurethane or acrylic, serve to secure against environmental elements, including wetness, abrasion, and chemicals. Additionally, coverings can enhance tactile comments and visual appeal, contributing to the general user experience. The selection of proper adhesives and layers is vital for enhancing performance and durability in varied applications throughout different markets, making sure that Membrane switches satisfy certain functional demands.

Substrate Selection Aspects

Substrate option plays an essential role in the manufacturing of Membrane switches, as it greatly affects their overall efficiency and resilience. Key products such as polyester, polycarbonate, and adaptable published circuit card (FPCBs) are commonly used for their unique residential or commercial properties. Polyester is favored for its cost-effectiveness and resistance to abrasion, making it suitable for applications with high wear. Polycarbonate offers superior clearness and influence resistance, perfect for settings needing high presence. FPCBs give boosted adaptability and are commonly utilized in complicated designs. The choice of substratum likewise influences variables like thermal security, chemical resistance, and ease of printing. Inevitably, choosing the appropriate substrate is important for guaranteeing the capability and durability of Membrane changes throughout various sectors.

The Layout Refine of Membrane Changes

The design process of Membrane switches is a crucial phase that greatly influences the functionality and aesthetics of the end product - membrane switch manufacturer. It begins with specifying the details demands of the application, including dimensions, button layout, and responsive feedback choices. Designers need to think about user communication, guaranteeing that the button is intuitive and accessible.Next, products are chosen based on longevity, versatility, and environmental resistance. The combination of graphics and branding elements is additionally vital, as it enhances aesthetic allure and interaction. Prototyping allows for repetitive screening, making it possible for changes based on individual comments and efficiency evaluations.Additionally, the layout needs to make up the electrical elements, such as circuits and connectors, guaranteeing reliability and convenience of use. Inevitably, an effective design harmonizes functionality, visual appeals, and individual experience, leading the way for reliable manufacturing and long-lasting efficiency in different industries

Printing Methods for Membrane Switches

The printing methods utilized in Membrane switch manufacturing play an important role in identifying the end product's high quality and capability. Screen printing offers benefits such as sturdiness and vibrant shade application, while digital printing innovations give flexibility and precision in layout. Recognizing these techniques can significantly affect the total effectiveness of Membrane buttons in various applications.

Display Printing Advantages

Numerous benefits make screen printing a preferred method for producing Membrane switches. This approach enables top quality, thorough styles and vibrant colors, which are important for individual interface applications. Display printing is specifically effective for applying thick ink layers, boosting durability and tactile responses. Furthermore, it provides exceptional attachment to various substrates, making sure longevity popular atmospheres. The process is economical for huge production runs, as it decreases setup time and waste. Display printing supports a wide range of inks, consisting of specialty and UV-curable alternatives, allowing flexibility in style. Its ability to create regular results across several units makes it a reliable choice for makers going best site for quality and performance in Membrane button production.

Digital Printing Innovations

Innovations in electronic printing modern technology are transforming the manufacturing of Membrane buttons, supplying suppliers innovative services that improve style versatility and efficiency. Digital printing permits for intricate designs and high-resolution graphics, making it possible for custom-made branding and capability without the limitations of typical techniques. This method decreases configuration times and expenses, facilitating shorter production runs and marginal waste, making it ideal for companies with varying demands. Additionally, developments in ink solutions give much better sturdiness and bond, guaranteeing durability in different settings. As sectors progressively seek complex and personalized designs, electronic printing sticks out as a necessary strategy, setting a brand-new standard in Membrane switch production. The combination of these advancements settings producers to meet advancing market needs properly.

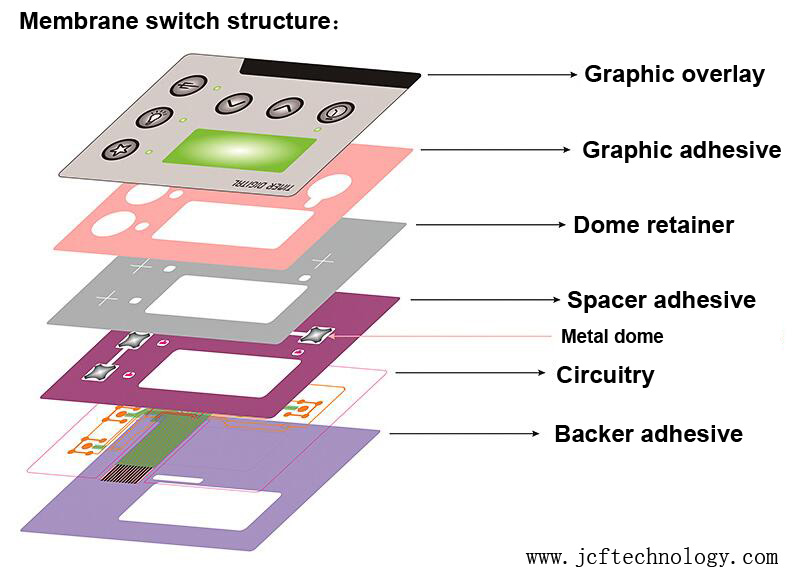

Setting up and Layering of Membrane Switch Parts

Careful assembly and layering of Membrane switch elements are essential to assuring performance and resilience. This process begins with the precise placement of various layers, including the visuals overlay, sticky, circuit layer, and support product. Each part should be meticulously placed to preserve electrical honesty and user interface responsiveness.During assembly, conductive traces are put on the circuit layer, generally made from products like polyester or polycarbonate. This layer is vital, as it sends signals when pressure is applied. The glue used for bonding these layers is additionally selected for its capability to endure environmental tensions while preserving a protected bond.Heat and stress are frequently used during the assembly process to ascertain that the layers stick correctly without jeopardizing the performance of the button. Focus is provided to the side securing to secure versus wetness and pollutants, safeguarding the long life of the Membrane button in various commercial applications.

Quality Assurance Procedures in Membrane Switch Manufacturing

Quality assurance steps play an important role in guaranteeing the dependability and performance of Membrane switches complying with the assembly and layering of their components. In the production procedure, several crucial assessments are conducted to support top quality standards. These include visual inspections for defects in printing and sticky application, in addition to functional examinations to validate the responsiveness of each switch.Additionally, ecological screening is done to evaluate the buttons' sturdiness against temperature level fluctuations and moisture direct exposure. Suppliers typically apply statistical procedure control (copyright) strategies to keep track of production uniformity, allowing early discovery of anomalies.Furthermore, traceability systems are established to track products and parts, ensuring responsibility and assisting in remembers if essential. Calibration of devices and adherence to industry standards are likewise essential to preserving item honesty. Collectively, these quality assurance measures guard the efficiency of Membrane switches throughout various applications, eventually enhancing client fulfillment.

Applications of Membrane Changes Across Different Industries

Membrane buttons are used across a diverse variety of sectors, showcasing their convenience and adaptability. In the medical industry, they offer water-proof and dependable interfaces for devices such as analysis tools and mixture pumps, making sure hygiene and simplicity of check here usage. The vehicle market employs Membrane buttons for dashboard controls, making it possible for smooth communication between the vehicle driver and vehicle systems.In customer electronic devices, these switches are discovered in appliances and portable tools, supplying a sleek, modern aesthetic while boosting capability. Industrial applications likewise leverage Membrane switches over for machinery control board, where sturdiness and resistance to severe problems are essential.Furthermore, the aerospace and defense markets utilize Membrane buttons for cabin instrumentation and communication systems, prioritizing integrity and efficiency under severe problems. Overall, Membrane switches play an important role in improving the individual experience and functional performance across numerous domains.

Often Asked Questions

For how long Does It Take to Manufacture a Membrane Switch?

The production time for a membrane layer switch normally ranges from a couple of days to a number of weeks - membrane switch manufacturer. Factors affecting this duration include style intricacy, material schedule, and manufacturing quantity, all influencing the total timeline markedly

What Is the Common Lifespan of a Membrane Switch?

The normal life-span of a membrane switch usually ranges from 1 to 5 million actuations, depending on aspects such as material high quality, environmental problems, and usage frequency, substantially affecting resilience and total performance.

Can Membrane Switches Over Be Customized for Particular Applications?

Membrane switches can undoubtedly be customized for specific applications. Their style adaptability allows for alterations in size, form, shades, and graphics, ensuring compatibility with special requirements throughout different industries and enhancing performance and individual experience.

Are Membrane Switches Over Environmentally Friendly?

The ecological effect of Membrane switches over varies. Some products used may not be eco-friendly, while improvements in producing procedures are progressively concentrating on sustainability, aiming to decrease waste and promote recyclable components in their production.

What Are the Common Failing Modes of Membrane Switches?

Typical failing modes of Membrane switches consist of delamination, glue failing, wear and tear from use, wetness access, and electric failings. These concerns can considerably influence capability, performance, and life-span in different applications across different markets. Membrane buttons can be customized to fit specific design needs, such as form, capability, and dimension, making them extremely adaptable.The construction generally entails several layers, including a graphic overlay, glue, and a circuit layer, which work with each other to develop a seamless customer experience. In Membrane switch production, the choice of key materials greatly affects performance and resilience. The automotive market utilizes Membrane buttons for control panel controls, making it possible for smooth communication in between the motorist and lorry systems.In consumer electronic devices, these switches are located in home appliances and portable devices, using a smooth, modern-day aesthetic while boosting functionality. Industrial applications likewise take advantage of Membrane changes for machinery control panels, where longevity and resistance to my blog harsh conditions are essential.Furthermore, the aerospace and protection fields utilize Membrane buttons for cabin instrumentation and interaction systems, prioritizing dependability and efficiency under extreme conditions. Membrane buttons can indeed be customized for certain applications.

Report this page